Get to Know Silencers

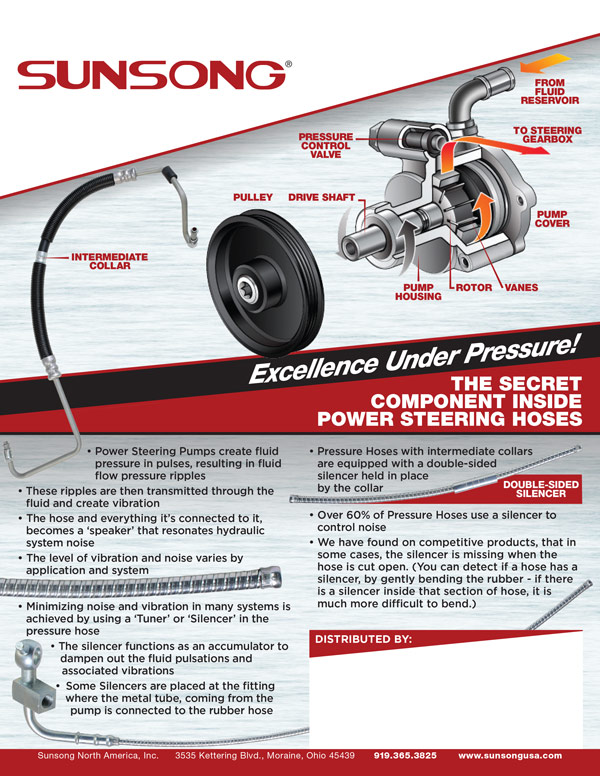

- Power Steering Pumps create fluid pressure in pulses, resulting in fluid flow pressure ripples

- These ripples are then transmitted through the fluid and create vibration

- The hose and everything it’s connected to it, becomes a ‘speaker’ that resonates hydraulic system noise

- The level of vibration and noise varies by application and system

- Minimizing noise and vibration in many systems is achieved by using a ‘Tuner’ or ‘Silencer’ in the pressure hose

- The silencer functions as an accumulator to dampen out the fluid pulsations and associated vibrations

- Some Silencers are placed at the fitting where the metal tube, coming from the pump is connected to the rubber hose

- Pressure Hoses with intermediate collars are equipped with a double-sided silencer held in place by the collar

- Over 60% of Pressure Hoses use a silencer to control noise

- We have found on competitive products, that in some cases, the silencer is missing when the hose is cut open. (You can detect if a hose has a silencer, by gently bending the rubber – if there is a silencer inside that section of hose, it is much more difficult to bend.)